Geosynthetics for Subgrade

When laying geosynthetics , first fill the surface layer of the soil that has been

crushed to the specified compaction standard, the distance between the adjacent two layers of

geosynthetics is not less than 3.0m, and the longitudinal overlap of the geosynthetics is 0.3m. The

geosynthetics must be tightening and fixing when laying, and then filling earth on it.

The composite geomembrane adopts two nonwovens and one membrane (the upper and lower parts are permeable nonwovens, the middle part is waterproof geomembrane ). The composite geomembrane or the corresponding standard composite geomembrane. Its weight is not less than 600g/m2, and the CBR bursting strength is not less than 2.5kN/m

The outstanding advantages of the composite geomembrane are integrating anti seepage and drainage, high tear strength, simple and convenient construction, large friction coefficient and good aging resistance It can solve the problem of subgrade drainage and tumbling mud The composite geomembrane uses plastic film as the anti seepage substrate and composited with nonwovens Its anti seepage performance mainly depends on the plastic film

The composite geomembrane adopts two nonwovens and one membrane (the upper and lower parts are permeable nonwovens, the middle part is waterproof geomembrane ). The composite geomembrane or the corresponding standard composite geomembrane. Its weight is not less than 600g/m2, and the CBR bursting strength is not less than 2.5kN/m

The outstanding advantages of the composite geomembrane are integrating anti seepage and drainage, high tear strength, simple and convenient construction, large friction coefficient and good aging resistance It can solve the problem of subgrade drainage and tumbling mud The composite geomembrane uses plastic film as the anti seepage substrate and composited with nonwovens Its anti seepage performance mainly depends on the plastic film

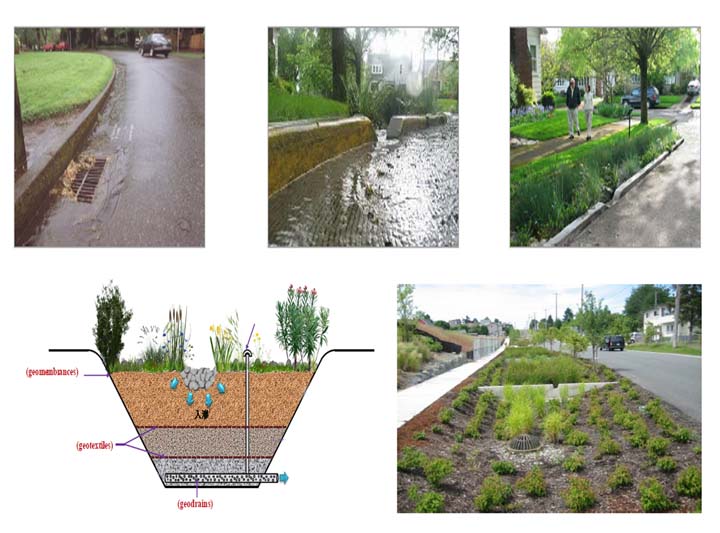

Geosynthetics for Low Impact Development

An approach to land development (or re-development) that works with nature to manage

stormwater as close to its source as possible. LID=Sponge City

Geosynthetics for Rail Way

Performance of geotextile : material used in reinforcement in permafrost areas. In

frozen soil region, the material is required to be resistant to cold, high acid and alkali

resistance, high durability, high tenacity and stable mechanical properties.

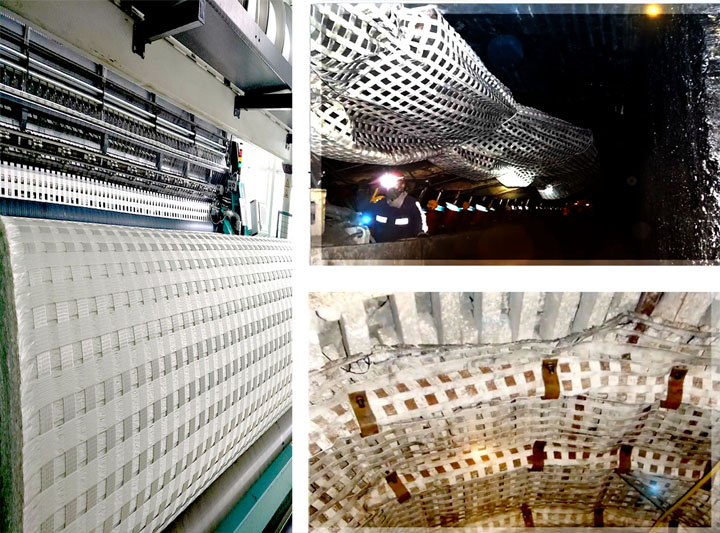

Geosynthetics for Coalmine

Performance of geosynthetics :Large mining height and working face mining support

material. The maximum tenacity of material is up to 1200kN/m, which replaces the traditional metal

support material, improves the remove speed of working face more than 4 times, which saves workers

and improves efficiency.